Ironing Melt Glide Waxes (aka Hot Waxing)

The bread and butter of glide waxing. Using an iron to apply paraffin blocks of melt wax is the classic, timeless way to get your skis going speedy. Using an iron is a skill and takes a bit to master, but if you work at it you won't have to on the trails! This is a glide waxing procedure so be sure not to glide wax the grip zones of your classic wax skis!

How-To Video

Step-by-Step

1) Begin by making sure your skis are clean. Scraped then brush gently with a steel or brass brush.

2) Clean your entire base with a liquid base cleaner or wax remover. Wipe as much dirt and dust off with Fiberlene or a shop towel.

3) Using a piece of Fibertex, energetically rub down the entire glide zone to remove any microscopic hairs or burrs in the base. Pink paper is also great for this. Then, repeat step 2 with a liquid base cleaner or wax remover and wipe away the dirt & dust. Let the solvents dry before continuing. Your ski is now clean and prepped for the hot wax.

4) Preheat your iron to the temperature recommended by the wax manufacturer for the particular wax you will be using. Temperatures for melt waxes are usually between 110C and 160C.

5) Melt a thin bead of the melt wax of the day down the ski on one side of the groove and back up the other side. Hold the iron with the plate vertically and touch one of the iron's bottom corners to the ski base. Hold the block of wax in the other hand and touch it to the iron to melt it. Move quickly to apply the right amount of wax. Make sure the iron's electrical cord isn't going to get caught or knock anything over. We do not recommend holding the iron above the ski and letting drips fall onto the ski. It is very difficult to wax consistently and you are more likely to use more product than you need when you miss the ski entirely and drip hot wax onto your feet. Another method to get the wax on the ski is one we use when we're applying precious, expensive melt waxes, Quickly tap the paraffin block to the bottom of the iron and in a quick motion drag the still-hot block along the base until all the liquified wax has stuck to the base. Repeat by quickly touching the block to the iron again and repeat until the entire glide zone is covered with a thin layer of wax.

6) Once the wax is on the ski set aside the block of wax and use the iron to melt the wax into the base. Hold the iron with a light pressure and run it down the ski from tip to tail careful not to let the iron rest in one place for too long. The paraffin should liquify for a couple of seconds but harden after a few seconds. If the wax is liquified for more than a few seconds you are not moving the iron fast enough. If you move the iron too fast the wax will become solid after a second or less. Try to completely cover one side of the ski's groove with the paraffin on the first pass by angling the pressure of the iron with your hand. Cover the other side of the groove on the second pass. On the third pass, apply pressure evenly across the ski.

7) Use a groove scraper to remove wax from the sidewalls and the ski's groove(s).

8) Let the ski cool. 5 minutes.

9) Using a sharp scraper, scrape off the excess paraffin. Scrape like you mean it, but don't press too hard. Angle the scraper forward and place your thumbs behind and at the bottom of the scaper. Scrape from tip to tail.

10) After scraping, pass a steel or brass brush 5-6 times using light pressure. Start at the tip and move to the tail.

11) If you like, you can polish the base using a horsehair and/or nylon hand brush or nylon roto brush.

12) Consider finishing your ski by adding structure with a rill tool if there is a lot of moisture in the snow, or if it is very cold or dry, finish the ski with pink paper or a structure tool for cold snow.

Products for Ironing Melt Glide Waxes (aka Hot Waxing)

-

Rode Merino LONG HAIR Wool Roto Brush

Regular price From $55.96 CADRegular priceUnit price / perRode Merino LONG HAIR Wool Roto Brush

Regular price From $55.96 CADRegular priceUnit price / perRode Merino LONG HAIR Wool Roto Brush

Regular price From $55.96 CADRegular priceUnit price / per -

Rode Glider Cleaner

Regular price From $41.96 CADRegular priceUnit price / per$0.00 CADSale price From $41.96 CAD17 in stockRode Glider Cleaner

Regular price From $41.96 CADRegular priceUnit price / per$0.00 CADSale price From $41.96 CADRode Glider Cleaner

Regular price From $41.96 CADRegular priceUnit price / per$0.00 CADSale price From $41.96 CAD -

Rode R30 RACING GLIDER VIOLET MELT WAX (-3C/-10C)

Regular price From $24.96 CADRegular priceUnit price / per$0.00 CADSale price From $24.96 CAD101 in stockRode R30 RACING GLIDER VIOLET MELT WAX (-3C/-10C)

Regular price From $24.96 CADRegular priceUnit price / per$0.00 CADSale price From $24.96 CADRode R30 RACING GLIDER VIOLET MELT WAX (-3C/-10C)

Regular price From $24.96 CADRegular priceUnit price / per$0.00 CADSale price From $24.96 CAD -

Rode Fiber Paper | 25m

Regular price $17.96 CADRegular priceUnit price / per$0.00 CADSale price $17.96 CAD172 in stock -

Rode R20 RACING GLIDER BLUE MELT WAX (-8C/-18C)

Regular price From $24.96 CADRegular priceUnit price / per$0.00 CADSale price From $24.96 CAD35 in stockRode R20 RACING GLIDER BLUE MELT WAX (-8C/-18C)

Regular price From $24.96 CADRegular priceUnit price / per$0.00 CADSale price From $24.96 CADRode R20 RACING GLIDER BLUE MELT WAX (-8C/-18C)

Regular price From $24.96 CADRegular priceUnit price / per$0.00 CADSale price From $24.96 CAD -

Rode RXD ENDURANCE GLIDER MELT WAX (10C/-20C)

Regular price From $34.96 CADRegular priceUnit price / per$0.00 CADSale price From $34.96 CAD108 in stockRode RXD ENDURANCE GLIDER MELT WAX (10C/-20C)

Regular price From $34.96 CADRegular priceUnit price / per$0.00 CADSale price From $34.96 CADRode RXD ENDURANCE GLIDER MELT WAX (10C/-20C)

Regular price From $34.96 CADRegular priceUnit price / per$0.00 CADSale price From $34.96 CAD -

Rode Roto Handle (100mm, 120mm, 200mm, or 300mm)

Regular price From $90.00 CADRegular priceUnit price / per$99.96 CADSale price From $90.00 CAD64 in stockRode Roto Handle (100mm, 120mm, 200mm, or 300mm)

Regular price From $90.00 CADRegular priceUnit price / per$99.96 CADSale price From $90.00 CADRode Roto Handle (100mm, 120mm, 200mm, or 300mm)

Regular price From $90.00 CADRegular priceUnit price / per$99.96 CADSale price From $90.00 CADSale -

Red Creek Groove Scraper

Regular price $6.97 CADRegular priceUnit price / per$0.00 CADSale price $6.97 CAD296 in stock -

Save $5.96

Save $5.96Rode Glider Cleaner Spray | 150mL

Regular price $16.00 CADRegular priceUnit price / per$21.96 CADSale price $16.00 CAD98 in stockSale -

Rode Soft Nylon Handbrush

Regular price $25.96 CADRegular priceUnit price / per$0.00 CADSale price $25.96 CAD53 in stock -

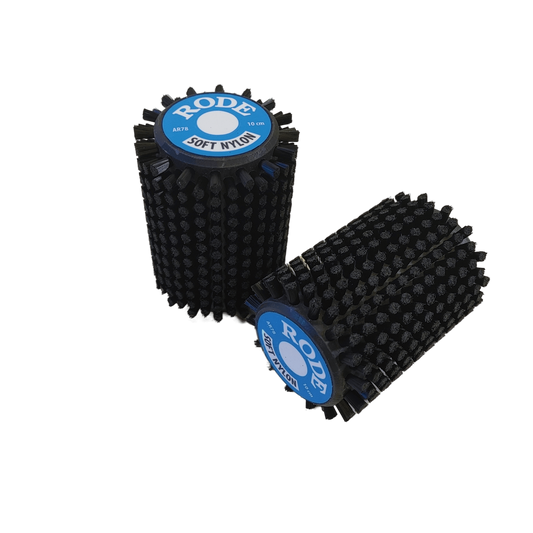

Rode Soft Nylon Roto Brush

Regular price From $69.96 CADRegular priceUnit price / perRode Soft Nylon Roto Brush

Regular price From $69.96 CADRegular priceUnit price / perRode Soft Nylon Roto Brush

Regular price From $69.96 CADRegular priceUnit price / per -

Rode FiberTex

Regular price From $13.96 CADRegular priceUnit price / per$0.00 CADSale price From $13.96 CAD22 in stockRode FiberTex

Regular price From $13.96 CADRegular priceUnit price / per$0.00 CADSale price From $13.96 CADRode FiberTex

Regular price From $13.96 CADRegular priceUnit price / per$0.00 CADSale price From $13.96 CAD -

Red Creek Diamond 3mm Scraper

Regular price $17.97 CADRegular priceUnit price / per$0.00 CADSale price $17.97 CAD113 in stock -

Red Creek Diamond 5mm Scraper

Regular price $19.97 CADRegular priceUnit price / per$0.00 CADSale price $19.97 CAD41 in stock -

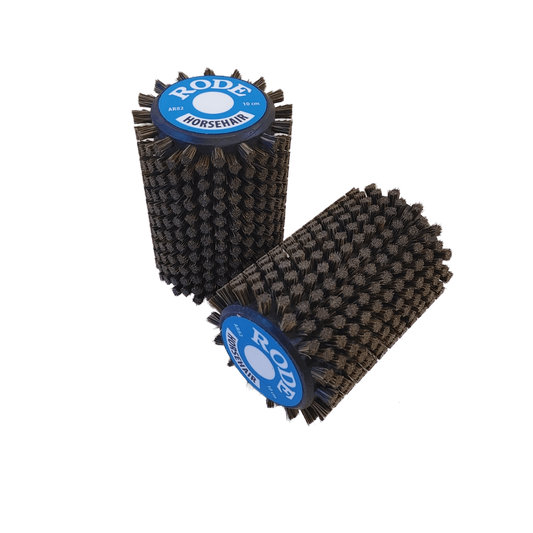

Rode Horsehair Roto Brush

Regular price From $69.96 CADRegular priceUnit price / perRode Horsehair Roto Brush

Regular price From $69.96 CADRegular priceUnit price / perRode Horsehair Roto Brush

Regular price From $69.96 CADRegular priceUnit price / per -

Red Creek Fluoro-Free Cold Melt Glide Wax (-1C/-20C)

Regular price From $59.97 CADRegular priceUnit price / per$0.00 CADSale price From $59.97 CAD1 in stockRed Creek Fluoro-Free Cold Melt Glide Wax (-1C/-20C)

Regular price From $59.97 CADRegular priceUnit price / per$0.00 CADSale price From $59.97 CADRed Creek Fluoro-Free Cold Melt Glide Wax (-1C/-20C)

Regular price From $59.97 CADRegular priceUnit price / per$0.00 CADSale price From $59.97 CAD -

Rode Horsehair Handbrush

Regular price $25.96 CADRegular priceUnit price / per$0.00 CADSale price $25.96 CAD27 in stock -

Rex Wax Racing Glide Blue Paraffin (-1C/-10C)

Regular price From $23.95 CADRegular priceUnit price / per$0.00 CADSale price From $23.95 CAD6 in stockRex Wax Racing Glide Blue Paraffin (-1C/-10C)

Regular price From $23.95 CADRegular priceUnit price / per$0.00 CADSale price From $23.95 CADRex Wax Racing Glide Blue Paraffin (-1C/-10C)

Regular price From $23.95 CADRegular priceUnit price / per$0.00 CADSale price From $23.95 CAD -

STAR Rotary Brush Handle with Cover FAST RELEASE/ IMPACT DRIVER- 140mm | 140mm

Regular price $173.00 CADRegular priceUnit price / per$0.00 CADSale price $173.00 CAD4 in stock -

Shop Towel for Ski & Snowboard Waxing

Regular price $6.95 CADRegular priceUnit price / per$0.00 CADSale price $6.95 CAD17 in stock -

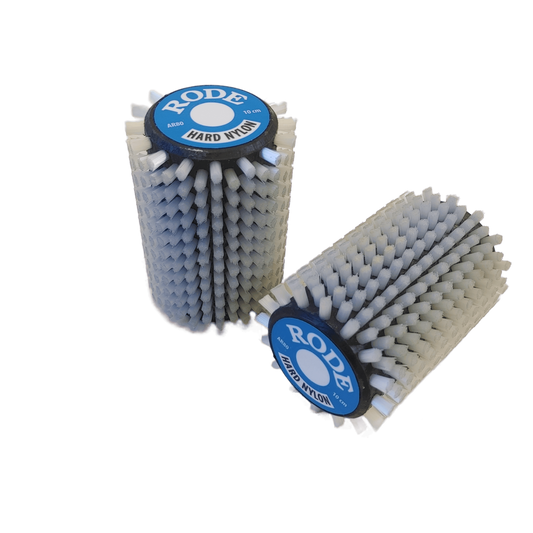

Rode Hard Nylon Roto Brush

Regular price From $69.96 CADRegular priceUnit price / perRode Hard Nylon Roto Brush

Regular price From $69.96 CADRegular priceUnit price / perRode Hard Nylon Roto Brush

Regular price From $69.96 CADRegular priceUnit price / per -

Rode Bronze Handbrush

Regular price $67.96 CADRegular priceUnit price / per$0.00 CADSale price $67.96 CAD113 in stock -

Red Creek Blue 6mm Nylon Racing Silver Hand Brush

Regular price $39.97 CADRegular priceUnit price / per$0.00 CADSale price $39.97 CADPre-Order Available -

Rode Merino SHORT HAIR Wool Roto Brush | 70mm

Regular price $55.96 CADRegular priceUnit price / per

Ski Waxing Safety Measures

Safe Ski Waxing: Protect Yourself While Prepping Your Skis

Ski waxing is key to great performance on the snow, but it involves chemicals, heat, dust, and fumes that require careful handling. Prioritizing safety protects your health and ensures the waxing process is both effective and responsible.

Follow these essential safety practices every time you wax:

1. Maximize Ventilation: Fresh Air is Crucial 🌬️

- Why? Hot waxing, solvents, and brushing release fumes and fine dust particles that shouldn't be inhaled.

- Best Practice: Wax outdoors whenever possible.

-

Indoors: Ensure excellent air exchange.

- Work near open windows or doors.

- Use powerful exhaust fans (like range hoods or dedicated extraction systems) vented directly outside.

- Simple fans just circulating air within the room are not sufficient.

- Speak Up: If you're in a shared facility (like a team wax room or event) and ventilation seems poor, notify staff or organizers immediately. If you can strongly smell fumes or wax, ventilation isn't adequate.

2. Protect Your Lungs: Use a Respirator 😷

-

Why? Waxing generates harmful airborne particles and fumes from multiple sources:

- Smoke/fumes from hot waxing irons or machines.

- Dust from scraping and brushing wax.

- Vapors from evaporating solvents in liquid waxes and cleaners.

- Dust from fleece/wool application methods.

- Fumes from heating grip waxes and klisters.

-

Action: Wear a respirator suitable for both particulates (dust) and organic vapors (fumes/solvents).

- Look for respirators with P100 particulate filters combined with organic vapor cartridges.

- Ensure a proper fit. Facial hair can prevent a good seal.

- Replace filters and cartridges according to the manufacturer's recommendations or when you notice smell/taste breakthrough or increased breathing resistance.

3. Protect Your Eyes: Wear Safety Glasses 👓

- Why? Dust, flying wax particles, and potential splashes from cleaners can irritate or injure your eyes.

- Action: Always wear safety glasses or goggles. A full-face respirator also provides eye protection.

4. Protect Your Skin: Wear Gloves 🧤

- Why? Waxes and solvents contain chemicals that can be absorbed through the skin or cause irritation.

- Action: Wear chemical-resistant gloves (nitrile gloves are a common and effective choice). This keeps your hands clean and prevents direct skin contact with potentially harmful substances.

5. Maintain a Safe Wax Room Environment 🚫

- Control Access: Only those actively involved in waxing should be in the immediate waxing area to minimize exposure for others.

- No Food or Drink: Never eat, drink, smoke, or store food in the waxing area. This prevents accidental ingestion of harmful residues.

- Cleanliness: Keep your workspace tidy. Clean up spills immediately and manage wax scrapings (see next point).

6. Handle Wax Waste Responsibly ♻️

- Why? Wax shavings and dust contain the same chemicals you're protecting yourself from during application. Proper disposal protects the environment and prevents contamination.

-

Action:

- Collect all wax shavings, dust, and used cleaning materials (paper towels, rags).

- Place them promptly into a sealed plastic bag or designated waste container.

- Dispose of according to local regulations. (Note: Regulations for fluorinated wax disposal might be stricter in some areas – check local rules).

7. Control Your Iron Temperature 🔥

- Why? Overheating wax creates significantly more fumes and can damage your ski base.

- Action: Always use the wax manufacturer's recommended temperature for your specific wax. Don't guess!

8. Handle Cleaners & Solvents with Extra Care 🧪

- Why? Base cleaners and liquid waxes often contain volatile organic compounds (VOCs) that are easily inhaled and can be flammable.

-

Action:

- Use solvents and cleaners sparingly.

- Ensure maximum ventilation when applying them.

- Keep containers sealed when not in use.

- Crucially: Keep solvents far away from heat sources like your waxing iron, space heaters, or open flames.

Your Health Comes First!

By consistently following these safety protocols, you protect yourself from potential respiratory issues, skin irritation, and other health effects. Safe waxing allows you to focus on getting the best performance from your skis and fully enjoy your time on the snow.