MasterWax Buyer/User Guide

MasterWax’s marquee products have long been their wool-apply waxes. “Wool-apply” (aka fleecing) use to be branded as a “revolutionary” ski waxing system, but that branding has aged. Nowadays, many high-level clubs, teams, and ski-service shops use the system. Many other wax companies have copied MasterWax’s wool-apply system. Wool-apply waxing has gone mainstream.

“Wool-application” glide waxing uses friction-heat generated by a rotating wool applicator to apply a thin layer of wax to a ski, or snowboard’s base.

MasterWax: A Real Sustainable future

MADE IN SWITZERLAND

NEW FOR 2024/2025!

MasterWax has a bunch of new waxes in their line-up for the new season! These waxes allow for faster top speeds, increased acceleration, and improved durability.

The Ultra8 and Professional lines has been re-vamped to exclude the fluoros but keep the speed. Also new to the Ultra8 line are a full range of powders!

FLUORO-FREE Ultra8 Wool-Apply Waxes

-

MasterWax Ultra8 FLUORFREE Cold Dark Wool-Apply Wax (-7C/-14C) | 20g

Regular price $289.96 CADRegular priceUnit price / per$0.00 CADSale price $289.96 CAD -

MasterWax Ultra8 FLUORFREE Cold Wool-Apply Wax (-7C/-14C) | 20g

Regular price $289.96 CADRegular priceUnit price / per$0.00 CADSale price $289.96 CAD -

MasterWax Ultra8 FLUORFREE Medium Wool-Apply Wax (-4C/-10C) | 20g

Regular price $289.96 CADRegular priceUnit price / per$0.00 CADSale price $289.96 CAD -

MasterWax Ultra8 FLUORFREE Wet Wool-Apply Wax (0C/-3C) | 20g

Regular price $289.96 CADRegular priceUnit price / per$0.00 CADSale price $289.96 CAD

FLUORO-FREE Ultra8 Powders

-

MasterWax Ultra8 FLUORFREE Cold Dark Powder (-7C/-18C) | 20g

Regular price $209.96 CADRegular priceUnit price / per$0.00 CADSale price $209.96 CAD -

MasterWax Ultra8 FLUORFREE Cold Powder (-7C/-18C) | 20g

Regular price $209.96 CADRegular priceUnit price / per$0.00 CADSale price $209.96 CAD -

MasterWax Ultra8 FLUORFREE Medium Powder (-4C/-10C) | 20g

Regular price $209.96 CADRegular priceUnit price / per$0.00 CADSale price $209.96 CAD -

MasterWax Ultra8 FLUORFREE Wet Powder | 20g (0C/-4C)

Regular price $209.96 CADRegular priceUnit price / per$0.00 CADSale price $209.96 CAD -

MasterWax Ultra8 FLUORFREE Wet Dark Powder | 20g (0C/-4C)

Regular price $209.96 CADRegular priceUnit price / per$0.00 CADSale price $209.96 CAD

FLUORO-FREE Professional Wool-Apply Waxes

-

MasterWax Professional FLUORFREE Wet Wool-Apply Wax (0C/-3C) | 20g

Regular price $209.96 CADRegular priceUnit price / per$0.00 CADSale price $209.96 CAD -

MasterWax Professional FLUORFREE Medium Wool-Apply Wax (-4C/-10C) | 20g

Regular price $209.96 CADRegular priceUnit price / per$0.00 CADSale price $209.96 CAD -

MasterWax Professional FLUORFREE Cold Wool-Apply Wax (-7C/-14C) | 20g

Regular price $209.96 CADRegular priceUnit price / per$0.00 CADSale price $209.96 CAD -

MasterWax Professional FLUORFREE Cold Dark Wool-Apply Wax (-7C/-14C) | 20g

Regular price $209.96 CADRegular priceUnit price / per$0.00 CADSale price $209.96 CAD

The MasterWax wool-apply ski waxing system is a fantastic way to get fast skis quickly without putting your heath at risk. Learn how to prepare your skis with cold-apply wax at the end of this article.

This article is a buyer’s guide to help you select the perfect products for your use case.

MasterWax has introduced 2 entirely new lines of fluoro-free racing glide waxes

to compliment the RACING FLUORFREE waxes. The Ultra8 and Professional lines has been revamped to replace their HF and LF counterparts in fluoro-free versions! These 3 lines give you all you need to choose from for all your racing or training needs.

Advantages of Cold-Apply Wax

With concerns raised by various studies over the past decade on the adverse effects to the health of wax techs working in enclosed spaces while engulfed in fumes from traditional waxing methods, MasterWax cold-apply offers a huge step in protecting the health of wax techs or anyone else who enters a wax room. Cold-apply does not produce smoke or fumes. Also, the amount of dust created in the waxing process is greatly reduced.

Impact on the environment is minimized when using cold-apply methods. The amount of wax that is wasted is minuscule. None of the wax used is scraped and brushed away into the garbage bin. Expect to wax 60-80 pairs of Nordic skate skis with a 20g block of MasterWax. The harmful solvents found in liquid glide waxes are completely avoided.

The quicker, simpler application process is a massive draw to this application method. The three-step clean, load, then buff process is faster than traditional waxing methods. It is also much easier to learn

for new back-shop employees or ski club volunteers. Because there are no hot temperatures or sharp tools involved, the risk of damaging equipment while waxing is mitigated. Find more information on how to use cold-apply wax at the end of this article!

The kilometrage you get out of waxes applied by this method tends to be good, but the standout feature is the raw speed of the skis it produces – particularly in warmer temperatures. Fleecing leaves the bare minimum amount of product on the base. This is fantastic because the ski bases’ natural structure or stone grind is maximally exposed to the snowpack. This helps the ski base do its job of getting rid of excess water from under the ski base. Fleeced waxes can be applied either on a completely bare, clean base or a paraffin base wax. As temperatures get colder, it’s recommended to fleece over a hard base paraffin.

MasterWax Kits: The Best Way to Go

If you're starting out with MasterWax, we recommend getting one of these kits. The kits come with all the wax, wools and attachments you need to get started with wool-apply waxing. Grabbing a bottle of Rode's Glide Cleaner is also recommended to help keep bases clean between wax applications.

1

/

of

6

Entry-level

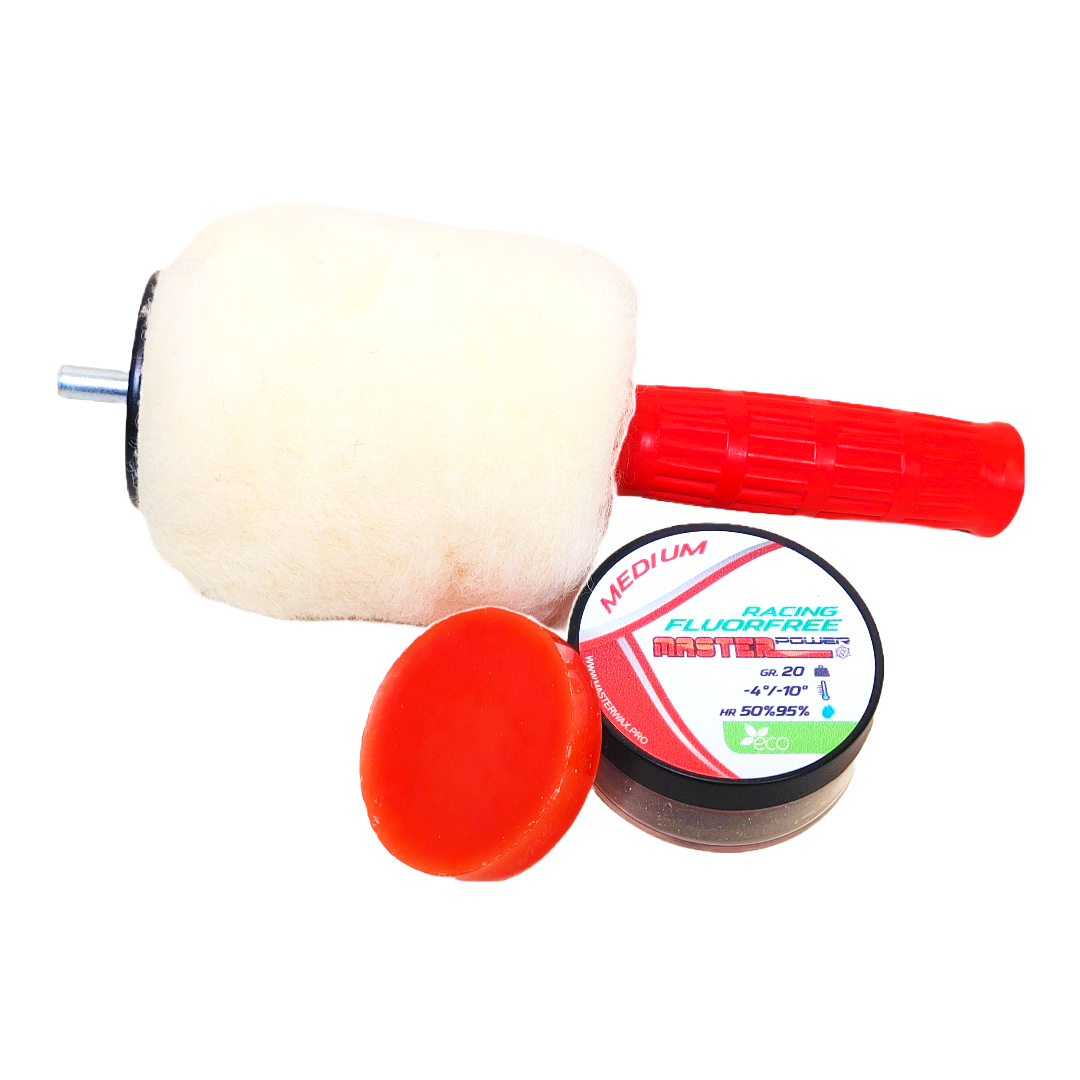

MasterWax RACING FLUORFREE Wool-Apply Entry Kit

Get the necessities for fast, safe, environmentally friendly skis! This Masterwax Entry Kit includes your choice of Fluoro-free Racing 20g Puck, a Wool Applicator, and a 12cm Roto Handle to attach to any standard drill. A 20g cold-apply puck can last for dozens of pairs of skis due to how little wax is actually applied, little usage with big performance! The low-dust, non-smoke cold-apply waxing system uses the friction generated with the wool applicators to efficiently apply the perfect layer of wax to the ski base. Incredible value! Buying each item individually is nearly more than twice as much. Get your kit today!

SKU:ENTERKITFMED

Regular price

$249.96 CAD

Regular price

$0.00 CAD

Sale price

$249.96 CAD

Unit price

/

per

Taxes, discounts and shipping calculated at checkout. $5 shipping on orders above $100 & Free-Shipping above $250 to all North American addresses.

Share

1

/

of

4

Entry to racing

MasterWax Professional FLUORFREE Wool-Apply Entry Kit

Get the necessities for fast, safe, environmentally friendly skis! This Masterwax Professional Entry Kit includes a Fluoro-free Professional 20g puck (Cold, Med, Wet, or Cold Dark), a Wool Applicator, a12cm Roto Cork, and a 12cm Roto Handle to attach to any standard drill. A 20g cold-apply puck can last for dozens of pairs of skis due to how little wax is actually applied, little usage with big performance! The low-dust, non-smoke cold-apply waxing system uses the friction generated with the wool applicators to efficiently apply the perfect layer of wax to the ski base. Incredible value! Buying each item individually is nearly more than twice as much. Get your kit today!

SKU:KITENTERMED

Regular price

$479.96 CAD

Regular price

$0.00 CAD

Sale price

$479.96 CAD

Unit price

/

per

Taxes, discounts and shipping calculated at checkout. $5 shipping on orders above $100 & Free-Shipping above $250 to all North American addresses.

Share

1

/

of

2

Most popular

MasterWax RACING FLUORFREE Wool-Apply Manual Kit

Get all you need for YEARS of fast, safe, environmentally friendly skis! This MasterWax Manual Kit includes the full line of RACING FLUOR-FREE cold apply waxes and the wool applicators you need to apply them. It all comes in a handy, padded travel case, with the 10cm Roto Handle as well. Now added is the option to get the 2 new waxes (Wet and Extreme Cold) and wools in the same case! A 20g cold-apply puck can last for dozens of pairs of skis due to how little wax is actually applied, little usage with big performance! The low-dust, non-smoke cold apply waxing system uses the friction generated with the wool applicators to efficiently apply the perfect layer of wax to the ski base. Incredible value! Buying each item individually is nearly $1000 ($1300 for all 6). Get your kit today!

SKU:KITFFJ

Regular price

$640.00 CAD

Regular price

$0.00 CAD

Sale price

$640.00 CAD

Unit price

/

per

Taxes, discounts and shipping calculated at checkout. $5 shipping on orders above $100 & Free-Shipping above $250 to all North American addresses.

Share

1

/

of

1

Racing value pack

MasterWax Professional FLUORFREE Wool-Apply Manual Kit

Get all you need for YEARS of fast, safe, environmentally friendly skis! This MasterWax Professional Manual Kit includes the standard line of Professional FLUOR-FREE cold apply waxes (minus Cold Dark) and the wool applicators you need to apply them. It all comes in a handy, padded travel case, with the 12cm Roto Handle as well. A 20g cold-apply puck can last for dozens of pairs of skis due to how little wax is actually applied, little usage with big performance! The low-dust, non-smoke cold apply waxing system uses the friction generated with the wool applicators to efficiently apply the perfect layer of wax to the ski base. Incredible value! Buying each item individually is nearly $1000. Get your kit today!

SKU:KITMANUALEFF

Regular price

$1,029.96 CAD

Regular price

$0.00 CAD

Sale price

$1,029.96 CAD

Unit price

/

per

Taxes, discounts and shipping calculated at checkout. $5 shipping on orders above $100 & Free-Shipping above $250 to all North American addresses.

Share

1

/

of

4

For big clubs/teams and the backshop

MasterWax RACING FLUORFREE Wool-Apply Engine Kit

Get a quick start with the MasterWax system with the fluoro-free Cold Apply Engine Kit! The MasterWax engine is the best and easiest way to use the innovative cold-apply MasterWax system. The kit comes with the Engine, 4-6 fluoro-free waxes (Medium, Cold, Transformed, and New Snow; possible addition of wet and extreme cold) and 4-6 Wool Applicators (one for each wax). The Engine has sturdy rubber feet to sit on a table top, or you can mount using screws/bolts. It is easily portable, however use care not to bump the spindle too hard! The Engine is the 110V for North American use.

SKU:KITMOTORFF

Regular price

$2,200.00 CAD

Regular price

$0.00 CAD

Sale price

$2,200.00 CAD

Unit price

/

per

Taxes, discounts and shipping calculated at checkout. $5 shipping on orders above $100 & Free-Shipping above $250 to all North American addresses.

Share

1

/

of

1

For big clubs/teams and the backshop

MasterWax Professional FLUORFREE Wool-Apply Engine Kit

Get a full start with the MasterWax system with the fluoro-free Cold Apply Engine Kit! The MasterWax engine is the best and easiest way to use the innovative cold-apply MasterWax system. The kit comes with the Engine, all 4 Professional fluoro-free waxes (Medium, Cold, Cold Dark, and Wet) and 4 Wool Applicators (one for each wax). The Engine has sturdy rubber feet to sit on a table top, or you can mount using screws/bolts. It is easily portable, however use care not to bump the spindle too hard! The Engine is the 110V for North American use.

SKU:KITMOTOREFF

Regular price

$2,499.96 CAD

Regular price

$0.00 CAD

Sale price

$2,499.96 CAD

Unit price

/

per

Taxes, discounts and shipping calculated at checkout. $5 shipping on orders above $100 & Free-Shipping above $250 to all North American addresses.

Share

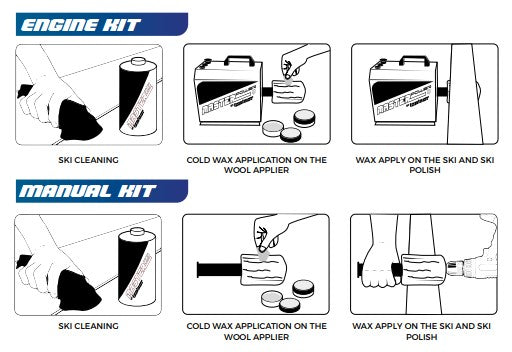

How to use MasterWax Products

- Begin by scraping a brushing out your base as thoroughly as possible. Use steel brushes if you have one. Bronze brushes are second-best.

- Clean your entire base with a base cleaner or wax remover. Wipe as much dirt and dust off with Fiberlene or shop towel.

- Using a piece of Fibertex, energetically rub-down the entire glide zone to remove any microscopic hairs or burrs in the base.

- If temperatures outside are below -7C, it is recommended to iron, scrape and brush a layer of very hard paraffin melt wax. A green wax is best, blue is second-best.

- In your head, mentally divide your wool applicator or roto-fleece in half. Load up half the applicator with

product by gently touching the puck to the rotating applicator. Leave the other half of the applicator clean. The clean side is for buffing later on. - Taking the clean ski and using medium force, run the loaded side of the applicator up and down the ski a few times to apply the product.

- Once the ski is loaded, switch to the clean side of the applicator and using slightly more pressure, buff out the ski

several more times. - Your ski should now be shiny and ready to go fast!

See this graphic and instructional videos (in Italian) below to learn more about how to successfully apply MasterWax products via drill or engine setups.

Great Add-Ons!

These products from other brands make the best add-ons for successful wool-apply waxing!

1

/

of

1

Grab some more!

Rode Merino LONG HAIR Wool Roto Brush

Achieve a superior ski base finish with Merino Wool Roto Brushes, perfect for the final polish of liquid waxes or for applying `Wool-Apply` waxes. A customer favorite, these brushes deliver an exceptional glide factor improvement, leaving ski bases looking lively, shiny, and primed for performance.

Ideal for the final polish of block and liquid waxes, this brush is a versatile addition to your ski prep kit. Delivers good results when loading skis with specialized `Wool Apply` aka `Cold-Apply` wax blocks like Rode RWs, MasterWax, STAR Wool-Apply Blocks, or Swix TSTs. (For great results with these products, load the block onto the ski with a shorter-haired wool, then polish with this one.) The 20mm wool filaments penetrate deep into ski base structures, leaving a durable wax layer that lasts over 10km.

Available in 70mm width (for 140mm roto handles) or 100mm width (for 100mm or 200mm roto handles). For best results, use separate brushes for each wax type to prevent cross-contamination, or consider one for warm wax and one for cold.

Note: Some shedding is normal with a new brush but will decrease with use as it breaks in. Elevate your ski performance with this must-have tool!

SKU:AR817

Regular price

$55.96 CAD

Regular price

$0.00 CAD

Sale price

$55.96 CAD

Unit price

/

per

Taxes, discounts and shipping calculated at checkout. $5 shipping on orders above $100 & Free-Shipping above $250 to all North American addresses.

Share

1

/

of

1

Prep your skis!

Rode Glider Cleaner Spray | 150mL

Use this Glider Cleaner to lift off dirt and old wax from your glide zones. Allows you to achieve a thorough ski base cleaning quickly without damaging the base - reviving it for the next waxing. It does not dry out the base, instead leaving a shiny aspect that ensures better sliding. Use the spray bottle to cover the base with glide cleaner, then brush with a nylon brush and/or metal brush before the solvents have a chance to dry to limit dust. Wipe off spent cleaner with a cloth and repeat cleaning until the cloth comes off free of visible grime. The 150mL spray bottles make it super simple to apply directly to your ski base. Also available in large 500mL and 1L bulk bottles with an open top.

SKU:AR18

Regular price

$21.96 CAD

Regular price

$0.00 CAD

Sale price

$21.96 CAD

Unit price

/

per

Taxes, discounts and shipping calculated at checkout. $5 shipping on orders above $100 & Free-Shipping above $250 to all North American addresses.

Share