STAR Buyer's Guide

When it comes to maximizing speed and performance in the fluoro-free era, STAR has quickly become a leader in ski wax innovation. With the FIS ban on fluorinated waxes, STAR set out to design a top-performing, fluoro-free wax line for competitive racing. One crucial discovery emerged early: new materials and additives responded differently depending on the application method. This means that, more than ever, how you apply the product matters. In this guide, we’ll explore STAR’s excellent product line and help you choose the right wax and application techniques to get the best results on race day.

Star NEXT: Born Fluoro-Free

STAR NEXT

A product labelled with "STAR NEXT" tells you two things: First, it is entirely fluoro-free, and second, it has the top-of-the-line best racing-level performance. The NEXT line has four form factors: Melt wax, powder, liquid, and wool-apply blocks. We'll start this buyer's guide by going over the new releases for the 2024/2025 season. Skip ahead if you want to learn more about selecting wax for specific snow conditions, and the application methods to get the most out of STAR products.

*NEW! NEXT Durables - Long Distance Base

The new products we're most excited about are the new STAR Durables. These waxes enhance the durability of your glide wax without impacting speed in nearly all snow types except for new snow in mid-temperature ranges. The liquid is a go-to first layer almost every time you head out; the powder is for maximum marathon durability, and the block form factor is for the convenience of wool-apply application. As usual, these durable waxes are often the absolute fastest option in your wax box in abrasive snow, so be sure to test them as the final layer in icy or cold snow.

-

STAR NEXT Durable Long Distance Base Liquid (Sponge Application) | 100ml

Regular price $90.00 CADRegular priceUnit price / per$0.00 CADSale price $90.00 CAD -

STAR NEXT Durable Long Distance Base Powder

Regular price From $90.00 CADRegular priceUnit price / per$0.00 CADSale price From $90.00 CADSTAR NEXT Durable Long Distance Base Powder

Regular price From $90.00 CADRegular priceUnit price / per$0.00 CADSale price From $90.00 CADSTAR NEXT Durable Long Distance Base Powder

Regular price From $90.00 CADRegular priceUnit price / per$0.00 CADSale price From $90.00 CAD -

STAR NEXT Durable Long Distance Fluoro-Free Racing Wool-Apply BLOCK | 28g

Regular price $85.00 CADRegular priceUnit price / per$0.00 CADSale price $85.00 CAD

*NEW! NEXT Dark Liquids

The STAR NEXT DARK liquids are an advancement in in STAR's offering for transformed snow crystals, such as icy, dirty, or old snow. These liquids are used as top coats, but durability is enhanced by applying a base wax underneath, such as the STAR Durable or STAR NEXT ironed-on melt waxes.

-

STAR NEXT DARK WARM Fluoro-Free Racing Liquid (Sponge Application) (0C/-5C) | 100ml

Regular price $90.00 CADRegular priceUnit price / per$0.00 CADSale price $90.00 CAD -

STAR NEXT DARK MED Fluoro-Free Racing Liquid (Sponge Application) (-3C/-8C) | 100ml

Regular price $90.00 CADRegular priceUnit price / per$0.00 CADSale price $90.00 CAD -

STAR NEXT DARK COLD Fluoro-Free Racing Liquid (Sponge Application) (-6C/-12C) | 100ml

Regular price $90.00 CADRegular priceUnit price / per$0.00 CADSale price $90.00 CAD

*NEW! NEXT Dark Powders

The STAR NEXT DARK Powders are the most concentrated dose of micro ceramics and graphite (among other ingredients) you can give to your ski bases. The DARK Powders enhance the durability and speed of your race skis in old, icy and/or dirty snow.

-

STAR NEXT DARK WARM Fluoro-Free Racing Powder (0C/-5C)

Regular price From $90.00 CADRegular priceUnit price / per$0.00 CADSale price From $90.00 CADSTAR NEXT DARK WARM Fluoro-Free Racing Powder (0C/-5C)

Regular price From $90.00 CADRegular priceUnit price / per$0.00 CADSale price From $90.00 CADSTAR NEXT DARK WARM Fluoro-Free Racing Powder (0C/-5C)

Regular price From $90.00 CADRegular priceUnit price / per$0.00 CADSale price From $90.00 CAD -

STAR NEXT DARK MED Fluoro-Free Racing Powder (-3C/-8C)

Regular price From $90.00 CADRegular priceUnit price / per$0.00 CADSale price From $90.00 CADSTAR NEXT DARK MED Fluoro-Free Racing Powder (-3C/-8C)

Regular price From $90.00 CADRegular priceUnit price / per$0.00 CADSale price From $90.00 CADSTAR NEXT DARK MED Fluoro-Free Racing Powder (-3C/-8C)

Regular price From $90.00 CADRegular priceUnit price / per$0.00 CADSale price From $90.00 CAD -

STAR NEXT DARK COLD Fluoro-Free Racing Powder (-6C/-12C)

Regular price From $90.00 CADRegular priceUnit price / per$0.00 CADSale price From $90.00 CADSTAR NEXT DARK COLD Fluoro-Free Racing Powder (-6C/-12C)

Regular price From $90.00 CADRegular priceUnit price / per$0.00 CADSale price From $90.00 CADSTAR NEXT DARK COLD Fluoro-Free Racing Powder (-6C/-12C)

Regular price From $90.00 CADRegular priceUnit price / per$0.00 CADSale price From $90.00 CAD

*NEW! All Conditions RACE & CANADA EXTRA DRY

The All Conditions Race Liquid and powders are safe when you don't want to risk having slow skis. They give you fast skis in nearly all snow types but with a tilt towards older snow for the All Conditions DARK Powder. The Canada Extra Dry says it all in the name: it's best in very low humidity and newer snow. A liquid version of the Canada Extra Dry will be available soon, and before you ask, it doesn't have ginger ale as its solvent!

-

STAR NEXT All Conditions Fluoro-Free Racing Liquid (Sponge Application) | 100ml

Regular price $90.00 CADRegular priceUnit price / per$0.00 CADSale price $90.00 CAD -

STAR NEXT All Conditions Fluoro-Free Racing Powder

Regular price From $90.00 CADRegular priceUnit price / per$0.00 CADSale price From $90.00 CADSTAR NEXT All Conditions Fluoro-Free Racing Powder

Regular price From $90.00 CADRegular priceUnit price / per$0.00 CADSale price From $90.00 CADSTAR NEXT All Conditions Fluoro-Free Racing Powder

Regular price From $90.00 CADRegular priceUnit price / per$0.00 CADSale price From $90.00 CAD -

STAR NEXT DARK All Conditions Fluoro-Free Racing Powder

Regular price From $90.00 CADRegular priceUnit price / per$0.00 CADSale price From $90.00 CADSTAR NEXT DARK All Conditions Fluoro-Free Racing Powder

Regular price From $90.00 CADRegular priceUnit price / per$0.00 CADSale price From $90.00 CADSTAR NEXT DARK All Conditions Fluoro-Free Racing Powder

Regular price From $90.00 CADRegular priceUnit price / per$0.00 CADSale price From $90.00 CAD -

STAR Canada Extra Dry Powder

Regular price From $90.00 CADRegular priceUnit price / per$0.00 CADSale price From $90.00 CADSTAR Canada Extra Dry Powder

Regular price From $90.00 CADRegular priceUnit price / per$0.00 CADSale price From $90.00 CADSTAR Canada Extra Dry Powder

Regular price From $90.00 CADRegular priceUnit price / per$0.00 CADSale price From $90.00 CAD

*NEW! S-Kick Waxes

A sequel to the STAR TARGET kick waxes, the S-line shores up performance in newer to transformed snow.

-

STAR S30 Stick Glazing Hardwax (3C/-1C) | 45g

Regular price $52.00 CADRegular priceUnit price / per$0.00 CADSale price $52.00 CAD -

STAR S25 Stick Warm Hardwax (1C/-4C) | 45g

Regular price $52.00 CADRegular priceUnit price / per$0.00 CADSale price $52.00 CAD -

STAR S20 Stick Medium Hardwax (-1C/-10C) | 45g

Regular price $52.00 CADRegular priceUnit price / per$0.00 CADSale price $52.00 CAD -

STAR S15 Stick Cold Hardwax (-6C/-18C) | 45g

Regular price $52.00 CADRegular priceUnit price / per$0.00 CADSale price $52.00 CAD -

STAR S10 Stick Very Cold Hardwax (-10C/-25C) | 45g

Regular price $52.00 CADRegular priceUnit price / per$0.00 CADSale price $52.00 CAD -

Save $13.00

Save $13.00STAR Stick Hardwax Bundle

Regular price $247.00 CADRegular priceUnit price / per$260.00 CADSale price $247.00 CADSale

The rest of STAR NEXT & Layering

As mentioned at the start of this post, the new materials and additives used in fluoro-free waxing respond differently depending on the application method. This means that, more than ever, how you apply the product matters. A crucial part of application is how you layer STAR NEXT waxes. Generally, you'll start with a layer of STAR Durable, then layer on a couple of coats of liquid and/or wool-apply top coats. However, there's more nuance, which we'll get into by looking into the rest of the STAR NEXT line:

NEXT Melt Wax (Base Wax)

These are the traditional waxes we're all familiar with - applied with an iron, cooled, then scraped and brushed. They are excellent for protecting and maintaining the ski base, helping with lubrication, and improving the glide and durability of "Top coat" waxes. Race ski waxing begins with a layer of NEXT melt wax, and a maintenance layer of these waxes every 100km keeps your ski bases in good condition.

-

STAR NEXT WARM Fluoro-Free Racing Melt Wax (0C/-5C)

Regular price From $48.00 CADRegular priceUnit price / per$0.00 CADSale price From $48.00 CADSTAR NEXT WARM Fluoro-Free Racing Melt Wax (0C/-5C)

Regular price From $48.00 CADRegular priceUnit price / per$0.00 CADSale price From $48.00 CADSTAR NEXT WARM Fluoro-Free Racing Melt Wax (0C/-5C)

Regular price From $48.00 CADRegular priceUnit price / per$0.00 CADSale price From $48.00 CAD -

STAR NEXT MED Fluoro-Free Racing Melt Wax (-3C/-8C)

Regular price From $48.00 CADRegular priceUnit price / per$0.00 CADSale price From $48.00 CADSTAR NEXT MED Fluoro-Free Racing Melt Wax (-3C/-8C)

Regular price From $48.00 CADRegular priceUnit price / per$0.00 CADSale price From $48.00 CADSTAR NEXT MED Fluoro-Free Racing Melt Wax (-3C/-8C)

Regular price From $48.00 CADRegular priceUnit price / per$0.00 CADSale price From $48.00 CAD -

STAR NEXT COLD Fluoro-Free Racing Melt Wax (-6C/-12C)

Regular price From $48.00 CADRegular priceUnit price / per$0.00 CADSale price From $48.00 CADSTAR NEXT COLD Fluoro-Free Racing Melt Wax (-6C/-12C)

Regular price From $48.00 CADRegular priceUnit price / per$0.00 CADSale price From $48.00 CADSTAR NEXT COLD Fluoro-Free Racing Melt Wax (-6C/-12C)

Regular price From $48.00 CADRegular priceUnit price / per$0.00 CADSale price From $48.00 CAD -

STAR NEXT POLAR Fluoro-Free Racing Melt Wax (-10C/-20C)

Regular price From $48.00 CADRegular priceUnit price / per$0.00 CADSale price From $48.00 CADSTAR NEXT POLAR Fluoro-Free Racing Melt Wax (-10C/-20C)

Regular price From $48.00 CADRegular priceUnit price / per$0.00 CADSale price From $48.00 CADSTAR NEXT POLAR Fluoro-Free Racing Melt Wax (-10C/-20C)

Regular price From $48.00 CADRegular priceUnit price / per$0.00 CADSale price From $48.00 CAD -

Save $9.60

Save $9.60STAR NEXT Melt Wax Bundle

Regular price From $182.40 CADRegular priceUnit price / per$192.00 CADSale price From $182.40 CADSTAR NEXT Melt Wax Bundle

Regular price From $182.40 CADRegular priceUnit price / per$192.00 CADSale price From $182.40 CADSTAR NEXT Melt Wax Bundle

Regular price From $182.40 CADRegular priceUnit price / per$192.00 CADSale price From $182.40 CADSale

NEXT Powder (Race Wax)

With the new STAR NEXT DARK Powders taking over duties in icy, dirty snow conditions, these standard STAR NEXT powders are now best used when skiing long distances in new snow when durability is a crucial factor. They are applied in micronized powder form and melted onto the ski base with a hot iron. These powders can be used as a base for "Top Coats" or independently. You will have to test if top coats improve the powder. Sometimes, the powder on its own is the fastest!

-

STAR NEXT WARM Fluoro-Free Racing Powder (0C/-5C)

Regular price From $81.00 CADRegular priceUnit price / per$0.00 CADSale price From $81.00 CADSTAR NEXT WARM Fluoro-Free Racing Powder (0C/-5C)

Regular price From $81.00 CADRegular priceUnit price / per$0.00 CADSale price From $81.00 CADSTAR NEXT WARM Fluoro-Free Racing Powder (0C/-5C)

Regular price From $81.00 CADRegular priceUnit price / per$0.00 CADSale price From $81.00 CAD -

STAR NEXT MED Fluoro-Free Racing Powder (-3C/-8C)

Regular price From $81.00 CADRegular priceUnit price / per$0.00 CADSale price From $81.00 CADSTAR NEXT MED Fluoro-Free Racing Powder (-3C/-8C)

Regular price From $81.00 CADRegular priceUnit price / per$0.00 CADSale price From $81.00 CADSTAR NEXT MED Fluoro-Free Racing Powder (-3C/-8C)

Regular price From $81.00 CADRegular priceUnit price / per$0.00 CADSale price From $81.00 CAD -

STAR NEXT COLD Fluoro-Free Racing Powder (-6C/-12C)

Regular price From $81.00 CADRegular priceUnit price / per$0.00 CADSale price From $81.00 CADSTAR NEXT COLD Fluoro-Free Racing Powder (-6C/-12C)

Regular price From $81.00 CADRegular priceUnit price / per$0.00 CADSale price From $81.00 CADSTAR NEXT COLD Fluoro-Free Racing Powder (-6C/-12C)

Regular price From $81.00 CADRegular priceUnit price / per$0.00 CADSale price From $81.00 CAD -

STAR NEXT POLAR Fluoro-Free Racing Powder (-10C/-20C)

Regular price From $81.00 CADRegular priceUnit price / per$0.00 CADSale price From $81.00 CADSTAR NEXT POLAR Fluoro-Free Racing Powder (-10C/-20C)

Regular price From $81.00 CADRegular priceUnit price / per$0.00 CADSale price From $81.00 CADSTAR NEXT POLAR Fluoro-Free Racing Powder (-10C/-20C)

Regular price From $81.00 CADRegular priceUnit price / per$0.00 CADSale price From $81.00 CAD -

Save $16.20

Save $16.20STAR NEXT Powder Bundles

Regular price From $307.80 CADRegular priceUnit price / per$324.00 CADSale price From $307.80 CADSTAR NEXT Powder Bundles

Regular price From $307.80 CADRegular priceUnit price / per$324.00 CADSale price From $307.80 CADSTAR NEXT Powder Bundles

Regular price From $307.80 CADRegular priceUnit price / per$324.00 CADSale price From $307.80 CADSale

NEXT Liquids (Top Coat)

These are the best fluoro-free liquids we've had the pleasure of testing. They're also the most friendly to work with owing to their rubbing alcohol solvent. They dry very fast - a welcome feature on race-day morning. The NEXT liquids are used as top coats to add extra speed or to adjust your wax to a specific temperature range. Remember to shake the bottle well before using the built-in sponge dabber to apply it to your skis. After the 1-2min dry time, STAR recommends brushing with nylon and then running a long-hair wool roto attached to an impact driver at 2900rpm to 3500rpm to finish. Sometimes, 2-3 layers of liquid in a "sandwich" format (e.g. Cold-Med-Cold) can produce lightning-fast skis. Blending with a layer of the wool-apply top coat can be fastest. These liquids tend to work best in newer snow now that the STAR DARK liquids tend to be better in old snow.

-

STAR NEXT WARM Fluoro-Free Racing Liquid (Sponge Application) | 100mL (0C/-5C)

Regular price $79.00 CADRegular priceUnit price / per$0.00 CADSale price $79.00 CAD -

STAR NEXT MED Fluoro-Free Racing Liquid (Sponge Application) | 100mL (-3C/-8C)

Regular price $79.00 CADRegular priceUnit price / per$0.00 CADSale price $79.00 CAD -

STAR NEXT COLD Fluoro-Free Racing Liquid (Sponge Application) | 100mL (-6C/-12C)

Regular price $79.00 CADRegular priceUnit price / per$0.00 CADSale price $79.00 CAD -

STAR NEXT POLAR Fluoro-Free Racing Liquid (Sponge Application) | 100mL (-10C/-20C)

Regular price $79.00 CADRegular priceUnit price / per$0.00 CADSale price $79.00 CAD -

Save $15.80

Save $15.80STAR NEXT Liquid Glide Wax Bundles

Regular price From $300.20 CADRegular priceUnit price / per$316.00 CADSale price From $300.20 CADSTAR NEXT Liquid Glide Wax Bundles

Regular price From $300.20 CADRegular priceUnit price / per$316.00 CADSale price From $300.20 CADSTAR NEXT Liquid Glide Wax Bundles

Regular price From $300.20 CADRegular priceUnit price / per$316.00 CADSale price From $300.20 CADSale

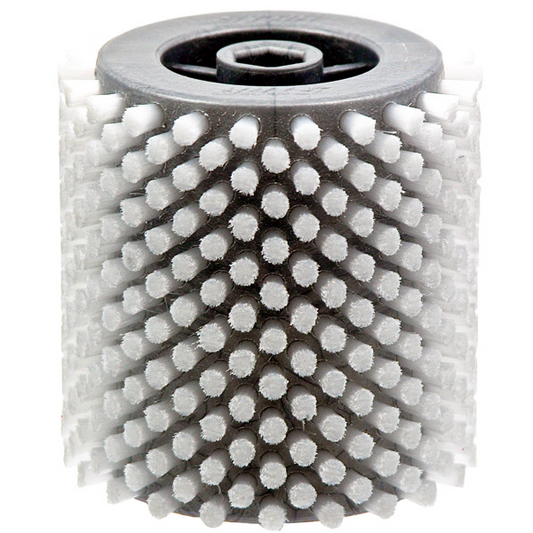

NEXT Wool-Apply (Top Coat)

Wool-apply waxes are applied by mounting the roller on a drill and rotating it, rubbing the wax onto the wool roller. Then, the rotating roller is applied to the ski base with light to moderate pressure and moved back and forth along the length of the ski, finishing by moving from the tip toward the tail of the ski. In one step, you apply the wax and polish it onto the base. Proper application should produce a shiny base and a small amount of "dust" but no smearing. It is best to finish the job with a nylon brush. In general, liquid top coat waxes are best for new snow, while wool-apply block waxes are best in medium-transformed snow. However, it would be best to experiment with both wax form-factors to see which type performs better in your particular snow conditions.

-

STAR NEXT WARM Fluoro-Free Racing Wool-Apply BLOCK (0C/-5C) | 28g

Regular price $85.00 CADRegular priceUnit price / per$0.00 CADSale price $85.00 CAD -

STAR NEXT MED Fluoro-Free Racing Wool-Apply BLOCK (-3C/-8C) | 28g

Regular price $85.00 CADRegular priceUnit price / per$0.00 CADSale price $85.00 CAD -

STAR NEXT COLD Fluoro-Free Racing Wool-Apply BLOCK (-6C/-12C) | 28g

Regular price $85.00 CADRegular priceUnit price / per$0.00 CADSale price $85.00 CAD -

STAR NEXT POLAR Fluoro-Free Racing Wool-Apply BLOCK (-6C/-20C) | 28g

Regular price $85.00 CADRegular priceUnit price / per$0.00 CADSale price $85.00 CAD -

STAR NEXT CASE Fluoro-Free Roto Fleece Kit

Regular price $830.00 CADRegular priceUnit price / per$0.00 CADSale price $830.00 CAD -

Save $13.50

Save $13.50STAR NEXT Wool-Apply BLOCK Bundle

Regular price From $256.50 CADRegular priceUnit price / per$270.00 CADSale price From $256.50 CADSTAR NEXT Wool-Apply BLOCK Bundle

Regular price From $256.50 CADRegular priceUnit price / per$270.00 CADSale price From $256.50 CADSTAR NEXT Wool-Apply BLOCK Bundle

Regular price From $256.50 CADRegular priceUnit price / per$270.00 CADSale price From $256.50 CADSale

Exploring More from STAR

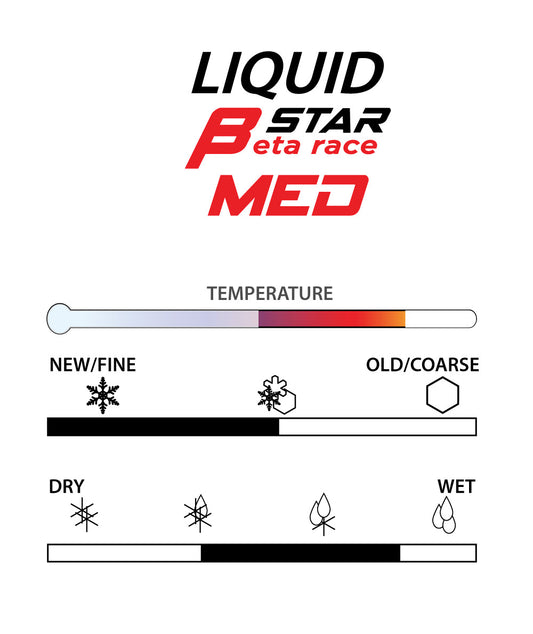

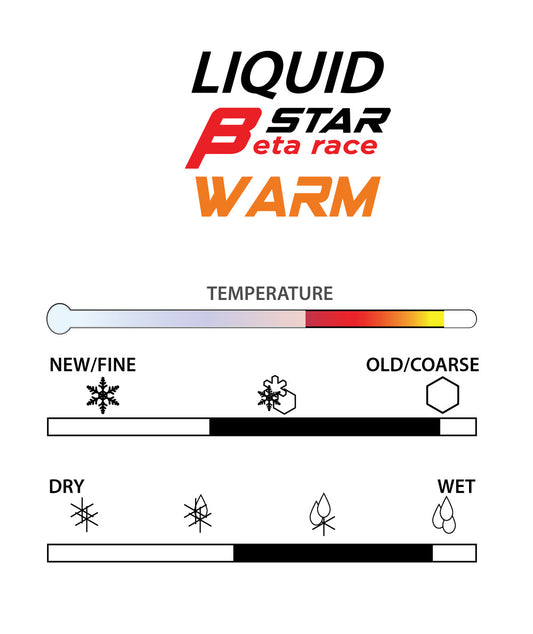

STAR BETA Glide Wax Line:

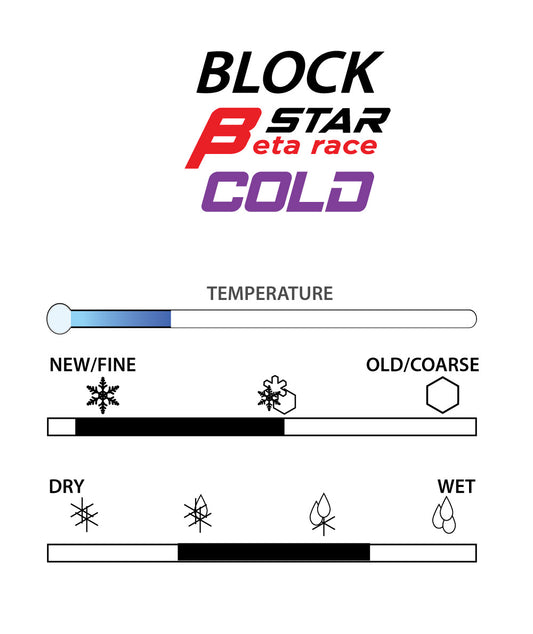

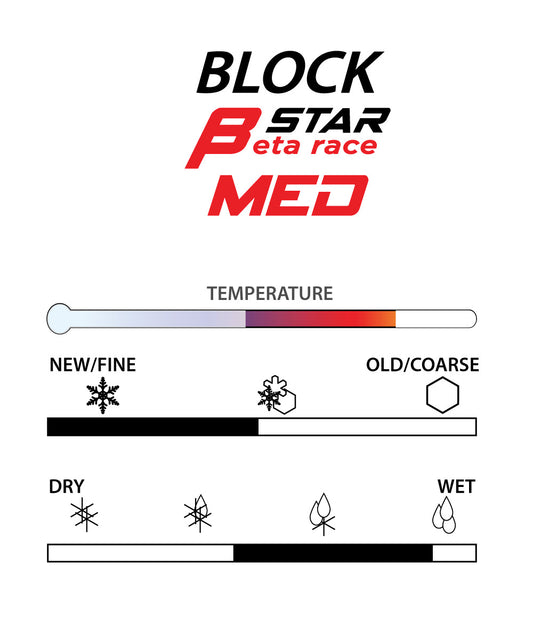

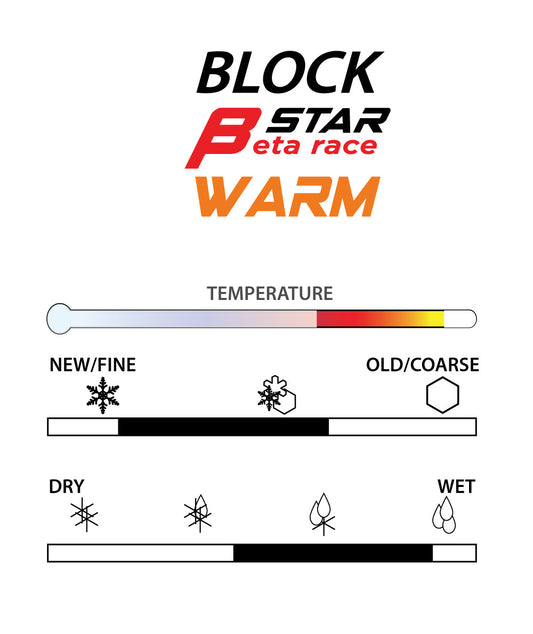

In addition to the STAR NEXT line, there is the BETA Research Program Race waxes. These waxes are better in dirty, old snow. There are two liquid toppers and three wool-apply toppers currently making up the BETA line. The liquids contain metallic ingredients that make them black in colour so the will stain your wools. Only the Cold Wool-Appy has the black additive, The Warm and Med Beta blocks have a light-coloured additive. With the addition of the NEXT DARK line, test out those in the non-dirty, old snows and reserve your BETAs for the late-season dirty snow.

-

STAR BETA MED Fluoro-Free Liquid (Sponge Applicator) (-3C/-8C) | 100ml

Regular price $90.00 CADRegular priceUnit price / per$0.00 CADSale price $90.00 CAD -

STAR BETA WARM Fluoro-Free Liquid (Sponge Applicator) | 100ml

Regular price $90.00 CADRegular priceUnit price / per$0.00 CADSale price $90.00 CAD -

STAR BETA COLD Fluoro-Free Wool-Apply BLOCK (-6C/-12C) | 28g

Regular price $90.00 CADRegular priceUnit price / per$0.00 CADSale price $90.00 CAD -

STAR BETA MED Fluoro-Free Wool-Apply BLOCK (-3C/-8C) | 28g

Regular price $90.00 CADRegular priceUnit price / per$0.00 CADSale price $90.00 CAD -

STAR BETA WARM Fluoro-Free Wool-Apply BLOCK | 28g

Regular price $90.00 CADRegular priceUnit price / per$0.00 CADSale price $90.00 CAD -

Save $13.50

Save $13.50STAR NEXT Wool-Apply BLOCK Bundle

Regular price From $256.50 CADRegular priceUnit price / per$270.00 CADSale price From $256.50 CADSTAR NEXT Wool-Apply BLOCK Bundle

Regular price From $256.50 CADRegular priceUnit price / per$270.00 CADSale price From $256.50 CADSTAR NEXT Wool-Apply BLOCK Bundle

Regular price From $256.50 CADRegular priceUnit price / per$270.00 CADSale price From $256.50 CADSale

Hardwaxes, Klister, Speciality Glide Waxes, and Irons

STAR has a full line if kick waxes, as well as some specialty glide waxes. Their irons are made in Italy to ensure their temperature during use is tightly controlled.

BETA Kick Waxes: These kick waxes come with klister pre-mixed in the tin. They're main use is in old/dirty or tricky conditions. The recipe comes with dirt-repelling ingredients for long-lasting speed in snow that's undergone a few freeze-thaw cycles. There are three temperature ranges in the BETA kick line.

S-Line Kick Waxes: These kick waxes are new to STAR in the 24/25 season. Designed to be a racier line for natural/new snow to compliment the popular BETA line. This line has a few different options to accommodate any condition.

Target Kick Wax Line: The STAR standard kick line includes and full range of kick waxes and klisters. These waxes are designed for both old and new snow.

Specialty Glide Waxes: The group of products are mainly geared toward high-volume users. Bulk-format waxes from STAR are some of the most affordable per gram. The MAP Black and Map 200 are fantastic base layers if you know you'll be skiing in very dirty snow or in new snow conditions where static charge can build up. The C1 and C2 hardening powders are sometimes a necessary addition to your wax application when you require more hardness and durability.

Irons: STAR stresses the importance of adhering to the recommended iron temperatures for all of their glide wax products. That's why they assemble their Irons in-house in Italy with custom components to make sure the metal plates maintain an accurate and stable temperature.

-

STAR Hardwaxes

STAR hardwaxes have been coming up more and more in tests with...

-

STAR Klisters

STAR has a broad range of klisters available. Whether you just need...

-

STAR Specialty Glide Waxes

STAR has a full range of base prep and specialty glide waxes...

-

STAR Irons

STAR has some of the best irons ever made! Though you may...

If you're more of a recreational skier looking to get in on the high-quality STAR wax technology, STAR waxes have something to offer: The NF line.

The NF line comes with two form-factors: the paraffin melt waxes for base wax, and the NF liquids as top coats. A good rule of thumb when using the NF line is to apply a layer of paraffin melt wax every 100km and a layer of liquid top coat before every outing.

-

STAR NF COLD Fluoro-Free Liquid (Sponge Application) | 100mL (-6C/-20C)

Regular price $42.00 CADRegular priceUnit price / per$0.00 CADSale price $42.00 CAD -

STAR NF MED Fluoro-Free Liquid (Sponge Application) | 100mL (-3C/-8C)

Regular price $42.00 CADRegular priceUnit price / per$0.00 CADSale price $42.00 CAD -

STAR NF WARM Fluoro-Free Liquid (Sponge Application) | 100mL (0C/-5C)

Regular price $42.00 CADRegular priceUnit price / per$0.00 CADSale price $42.00 CAD -

STAR NF POLAR Fluoro-Free Paraffin (-10C/-20C)

Regular price From $35.00 CADRegular priceUnit price / per$0.00 CADSale price From $35.00 CADSTAR NF POLAR Fluoro-Free Paraffin (-10C/-20C)

Regular price From $35.00 CADRegular priceUnit price / per$0.00 CADSale price From $35.00 CADSTAR NF POLAR Fluoro-Free Paraffin (-10C/-20C)

Regular price From $35.00 CADRegular priceUnit price / per$0.00 CADSale price From $35.00 CAD -

STAR NF COLD Fluoro-Free Paraffin (-6C/-12C)

Regular price From $35.00 CADRegular priceUnit price / per$0.00 CADSale price From $35.00 CADSTAR NF COLD Fluoro-Free Paraffin (-6C/-12C)

Regular price From $35.00 CADRegular priceUnit price / per$0.00 CADSale price From $35.00 CADSTAR NF COLD Fluoro-Free Paraffin (-6C/-12C)

Regular price From $35.00 CADRegular priceUnit price / per$0.00 CADSale price From $35.00 CAD -

STAR NF MED Fluoro-Free Paraffin (-3C/-8C)

Regular price From $35.00 CADRegular priceUnit price / per$0.00 CADSale price From $35.00 CADSTAR NF MED Fluoro-Free Paraffin (-3C/-8C)

Regular price From $35.00 CADRegular priceUnit price / per$0.00 CADSale price From $35.00 CADSTAR NF MED Fluoro-Free Paraffin (-3C/-8C)

Regular price From $35.00 CADRegular priceUnit price / per$0.00 CADSale price From $35.00 CAD -

STAR NF WARM Fluoro-Free Paraffin (0C/-5C)

Regular price From $35.00 CADRegular priceUnit price / per$0.00 CADSale price From $35.00 CADSTAR NF WARM Fluoro-Free Paraffin (0C/-5C)

Regular price From $35.00 CADRegular priceUnit price / per$0.00 CADSale price From $35.00 CADSTAR NF WARM Fluoro-Free Paraffin (0C/-5C)

Regular price From $35.00 CADRegular priceUnit price / per$0.00 CADSale price From $35.00 CAD -

STAR LG20 WARM Liquid Glide Wax (Sponge Applicator) (5C/-10C) | 75ml

Regular price $33.00 CADRegular priceUnit price / per$0.00 CADSale price $33.00 CAD -

STAR LG40 COLD Liquid Glide Wax (Sponge Applicator) (-8C/-20C) | 75ml

Regular price $33.00 CADRegular priceUnit price / per$0.00 CADSale price $33.00 CAD

Fluoro-Free Ski Wax for Racing: STAR "NEXT"

STAR Roto Brush System

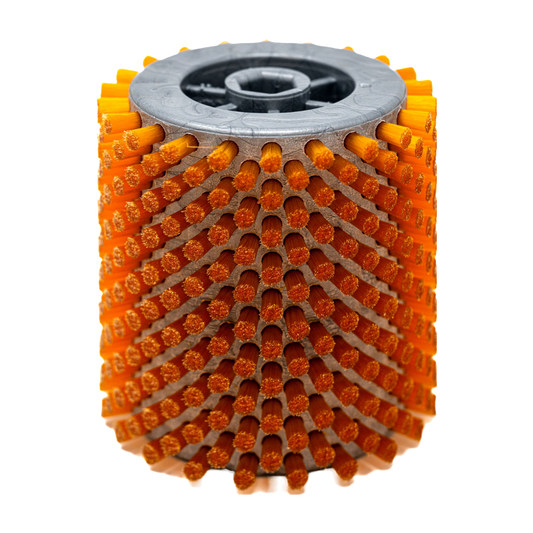

We are enthusiastic supporters of the STAR Roto Brush system, considering it to be the most well-designed range of brush products for fluoro-free waxing. Our inventory exclusively features the 70mm brushes paired with 140mm handles, as we believe these sizes offer the optimal solution for our cross-country skier clientele.

One notable advantage is the ability to dual load two 70mm roto brushes on the 140mm handles, providing an ideal setup for wool-apply waxing. This is particularly useful in common practices like dual loading a nylon and wool applicator. The versatility of these brushes caters to various waxing techniques.

Additionally, the hex axels adhere to the industry-standard 10mm width, ensuring compatibility with roto brushes from any other brand. It's important to note that while these brushes offer versatility, the width should not exceed 140mm to fit perfectly on the handles. This feature enhances convenience and allows for seamless integration with other tools in your ski maintenance kit.

Roto brushes perform several functions in ski waxing. STAR breaks these functions down into 4 categories:

Surface Wax Removal: To break up and remove excess wax left over after scaping.

Cleaning Structure: To expose your ski bases' stone grind pattern.

Wax Film Management: Very important in fluoro-free waxing; getting the right thickness of your fluoro-free wax layers can have an outsized impact on the speed of your skis.

Polishing/Finishing: For the final arrangement of the wax material over your ski bases.

-

STAR Rotary Brush Handle | 140mm

Regular price $155.00 CADRegular priceUnit price / per$0.00 CADSale price $155.00 CAD -

STAR Rotary Brush Handle with Cover FAST RELEASE/ IMPACT DRIVER- 140mm | 140mm

Regular price $173.00 CADRegular priceUnit price / per$0.00 CADSale price $173.00 CAD -

STAR Wool Fleece Roto Brush Short Hair 12mm

Regular price From $135.00 CADRegular priceUnit price / per$0.00 CADSale price From $135.00 CADSTAR Wool Fleece Roto Brush Short Hair 12mm

Regular price From $135.00 CADRegular priceUnit price / per$0.00 CADSale price From $135.00 CADSTAR Wool Fleece Roto Brush Short Hair 12mm

Regular price From $135.00 CADRegular priceUnit price / per$0.00 CADSale price From $135.00 CAD -

STAR Wool Fleece Roto Brush Long Hair 22mm

Regular price From $148.00 CADRegular priceUnit price / per$0.00 CADSale price From $148.00 CADSTAR Wool Fleece Roto Brush Long Hair 22mm

Regular price From $148.00 CADRegular priceUnit price / per$0.00 CADSale price From $148.00 CADSTAR Wool Fleece Roto Brush Long Hair 22mm

Regular price From $148.00 CADRegular priceUnit price / per$0.00 CADSale price From $148.00 CAD -

STAR Hard Blue Nylon Roto Brush | 70mm

Regular price $128.00 CADRegular priceUnit price / per$0.00 CADSale price $128.00 CAD -

STAR Soft White Nylon Roto Brush | 70mm

Regular price $128.00 CADRegular priceUnit price / per$0.00 CADSale price $128.00 CAD -

STAR Gold Nylon Roto Brush

Regular price From $135.00 CADRegular priceUnit price / per$0.00 CADSale price From $135.00 CADSTAR Gold Nylon Roto Brush

Regular price From $135.00 CADRegular priceUnit price / per$0.00 CADSale price From $135.00 CADSTAR Gold Nylon Roto Brush

Regular price From $135.00 CADRegular priceUnit price / per$0.00 CADSale price From $135.00 CAD -

STAR Natural Fiber Roto Brush | 70mm

Regular price $128.00 CADRegular priceUnit price / per$0.00 CADSale price $128.00 CAD -

STAR Unicorn Hair Roto Brush | 70mm

Regular price $150.00 CADRegular priceUnit price / per$0.00 CADSale price $150.00 CAD -

STAR Horse Hair Roto Brush | 70mm

Regular price $135.00 CADRegular priceUnit price / per$0.00 CADSale price $135.00 CAD -

STAR Horse Hair/Bronze Roto Brush | 70mm

Regular price $188.00 CADRegular priceUnit price / per$0.00 CADSale price $188.00 CAD -

STAR Steel Roto Brush | 70mm

Regular price $315.00 CADRegular priceUnit price / per$0.00 CADSale price $315.00 CAD -

STAR Roto Cork | 70mm

Regular price $124.00 CADRegular priceUnit price / per$0.00 CADSale price $124.00 CAD -

STAR Felt Roto Brush | 70mm

Regular price $179.00 CADRegular priceUnit price / per$0.00 CADSale price $179.00 CAD -

STAR Empty Roto Case

Regular price $137.00 CADRegular priceUnit price / per$0.00 CADSale price $137.00 CAD -

STAR PRO CASE Roto Brush Kit

Regular price $926.00 CADRegular priceUnit price / per$0.00 CADSale price $926.00 CAD -

STAR NEXT CASE Fluoro-Free Roto Fleece Kit

Regular price $830.00 CADRegular priceUnit price / per$0.00 CADSale price $830.00 CAD -

STAR BASE CASE Roto Brush Kit

Regular price $545.00 CADRegular priceUnit price / per$0.00 CADSale price $545.00 CAD